An encounter with Transformers-like robots ended up transforming Dr Mohan Rajesh Elara’s (AP Mohan) career plans.

He was pursuing his master's in consumer electronics at the Nanyang Technological University in 2005 when he was introduced to designing robots. Like Bumblebee and Optimus Prime, iconic Autobots from the pop culture hit, they could shape-shift to serve different purposes – albeit on a smaller scale.

Fascinated, AP Mohan decided to switch fields from integrated circuit design to robotics.

“I got a sense of satisfaction from getting an artificial machine to come to life. It was truly inspiring to see a system think, process and react and make an impact on the environment,” he explained.

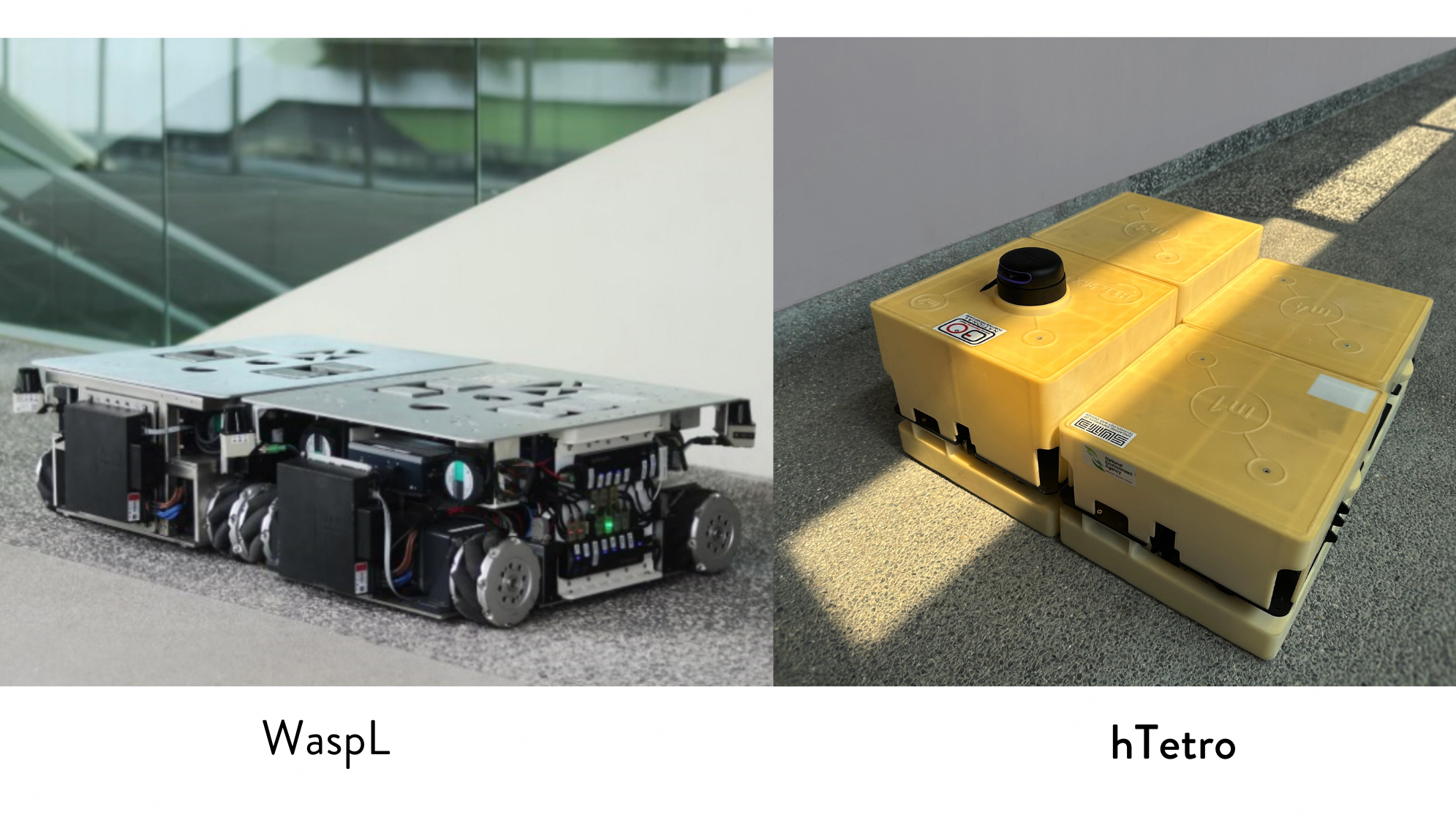

For instance, he worked on “hTetro”, a robot launched in 2017 that can morph into seven different configurations to clean spaces that most smart vacuums cannot reach. Unsurprisingly, it takes inspiration from the Tetris puzzle game.

AP Mohan, now an Associate Professor with the Engineering Product Development Pillar at the Singapore University of Technology and Design, believes such shape-changing inventions could be adapted for the Built Environment (BE) sector, which often deals with tight spaces.

Applications in BE

With 18 years of experience in robotics and artificial intelligence (AI) research, AP Mohan foresees uses in three main applications – transportation, inspection and manufacturing.

Many hospitals have already been utilising goods-moving robots for many years, which has allowed the technology to develop and mature. These robots can now move not only along a horizontal axis, but also climb stairs and communicate with lifts to move between different levels of buildings.

The concept of nesting will further cut down on redundancy. For example, instead of using multiple different-sized robots – each with different charging stations and training manuals – to move objects of varying sizes, users can have a collection of just one type using “WaspL”, a reconfigurable logistic robot. This new development allows robots to combine as a singular entity to move larger goods and separate for smaller ones.

Robots can be deployed for inspection to perform safety checks such as identifying microscopic cracks in glass panels. AP Mohan was part of a successful project in 2018 that developed robots which can move around and examine the external surfaces of aircraft.

With slight tweaks, he says these technologies can be adapted for use in the BE sector as well. And as technology continues to improve, he anticipates robots to take over large-scale tasks in manufacturing like tiling and painting.

The Right Robot for the Right Job

However, despite the vast possibilities for robotics in the BE industry, greater collaboration is needed to better understand and apply the technology in actual use cases

“Unlike the service domain, which is our everyday space, robot designers and engineers may not get the chance to go to a construction site,” AP Mohan explained. Without an understanding of what specific issues need to be resolved, it makes it difficult for them to create robots specific to the sector.

He added: “The partnership between the domain expert and the tech expert is critical to have the right robot and the right workflow.”

This is why he thinks the Built Environment Accelerate to Market Programme (BEAMP) is a good way to support the development of his goods-moving and inspection robots as well as to pilot and testbed it on a larger scale.

Launched in 2019, BEAMP is a multi-agency initiative that aims to build a vibrant innovation ecosystem for the BE sector and give innovators access to domain-specific knowledge.

The programme provides them with the tools necessary to adapt existing technologies to the industry and speeds up the process of bringing products to market.

Dragonfly and Koi class of mosquito control robots

Dragonfly and Koi class of mosquito control robots

Faster and Better Bots

With AI and automation set to redefine the future of work, robots will also play an indispensable role in the BE sector – which already faces a manpower crunch.

“A BE sector without robotics is an alternative future that does not exist. With the current trend, the use of robots will only accelerate,” said AP Mohan.

The development of AI and the fifth-generation (5G) mobile network will also push robotics to greater heights. With AI, robots will be able to learn faster and overcome challenges better than ever. The greater performance and speeds that come with 5G will also grant users better real-time control and support of their robots.

Like mobile phones, which started as a device made solely for communication before progressing to be so much more, AP Mohan believes robotics will see a similar transformation. “With more robots – diverse ones too – they will only evolve to become better and better.”

AP Mohan also hosted the first Built Environment Innovation Exchange (BEIX) at the Singapore University of Technology and Design (SUTD), where he and his team demonstrated the potential use of reconfigurable robots for the BE sector. This is an initiative of the Building and Construction Authority's (BCA) Built Environment Innovation Hub (BEIH). BEIH is a collaborative space for the industry to connect like-minded individuals, showcase innovative technologies, and best practices, augmenting the transfer of ideas and knowledge to accelerate transformation of the Built Environment sector.