Imagine this – a construction worker, with sweat dripping from his face, is carrying bulky ceiling boards which limit his vision. As a result, he fails to notice an open manhole behind him – nearly falling into it.

The near-miss incident is captured in real-time by his smartwatch and an artificial intelligence (AI)-powered CCTV camera in the area. The devices promptly send an alert to the supervisor in charge, who then gives immediate instructions to cover the manhole and address the safety hazard.

What if the same smartwatch is also able to gauge if the worker is spending the right amount of time on his tasks to ensure they are done correctly and efficiently?

This is the future of workplace safety, with technology reshaping construction sites and enhancing productivity – a vision shared by the Workplace, Safety and Health (WSH) Technology team.

Set up in late 2019 as a unit of the WSH Institute within the Occupational Safety and Health Division in the Ministry of Manpower, the WSH Tech team works with government agencies, technology vendors and institutes of higher learning in the tech ecosystem to identify and develop game-changing WSH solutions that can prevent workplace accidents by either replacing the worker from the hazardous condition, improving his situational awareness or reducing his chances of human error. A leader in the WSH tech space, the team also raises awareness of good solutions to industry and drives their adoption .

It is of particular concern this year, as workplace fatalities have spiked, mainly due to preventable safety lapses, bucking the trend of an overall decrease in fatal injuries in recent years.

“WSH technology can be game-changing in preventing accidents, as it can change the way work is done, provide close monitoring and alerts as well as reduce human errors ” shared Mr Gerald Yeo, Assistant Director (WSH Technology) at WSH Institute.

|

|

Mr Gerald Yeo, Assistant Director (WSH Technology) at WSH Institute. Mr Gerald Yeo, Assistant Director (WSH Technology) at WSH Institute.

|

|

So far, technologies to prevent the more common injuries such as slips, trips and falls (STFs for short) have been implemented in the facilities management (FM) sector. The plan is to introduce these technologies to construction sites in Singapore.

These moves are set to improve not just safety but also productivity in the Built Environment sector.

TURNING INNOVATIVE IDEAS INTO MARKET SOLUTIONS

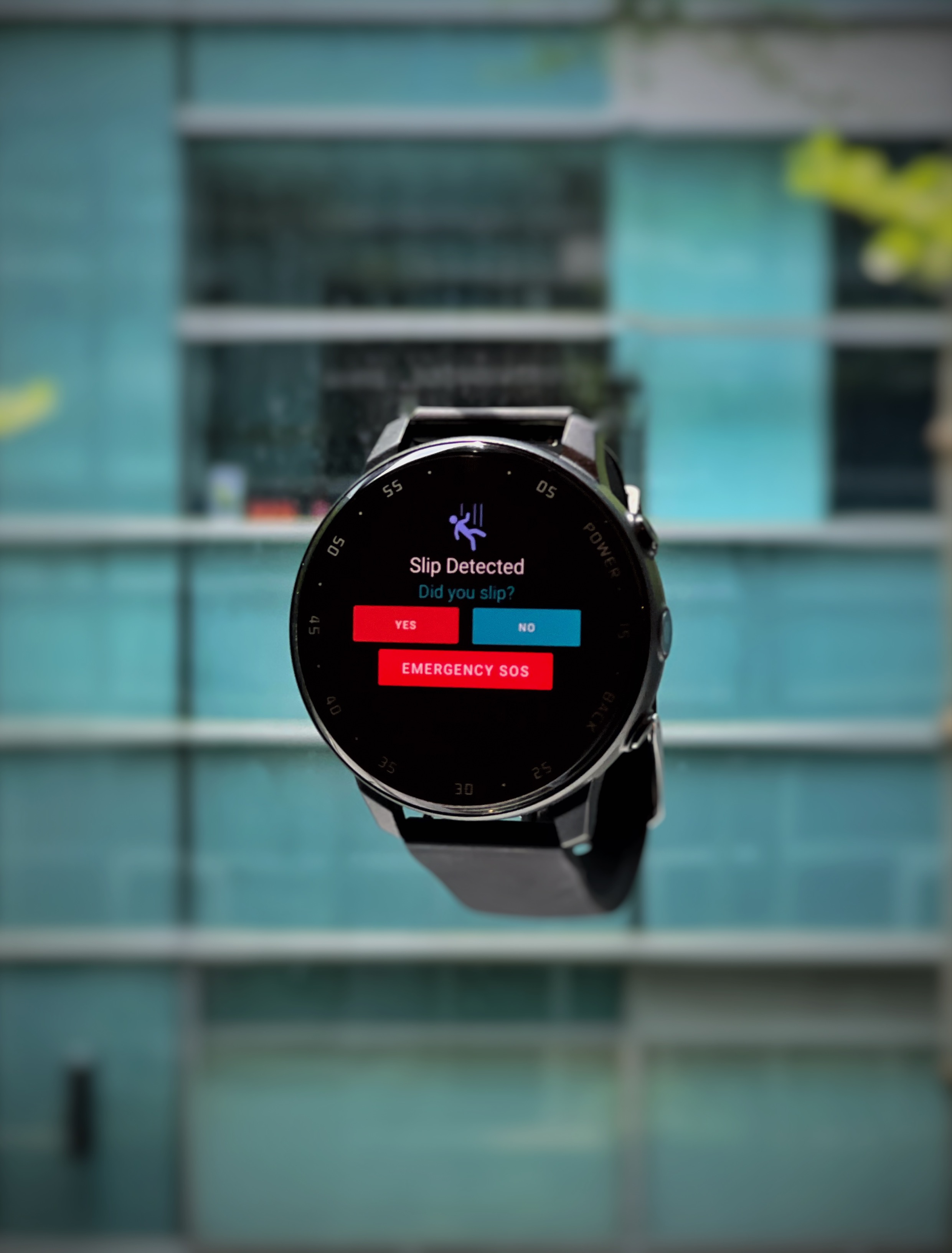

While there is technology in smart watches that is commonly used for geriatric care to notify when an elderly person suffers a fall, the WSH Technology team aims to go a step further with such wearable gadgets.

“Those technologies are reactive, but what we were interested in is prevention,” said Mr Yeo, referring to accidents on construction sites.

To fast-track development of innovative solutions, the WSH Technology team launched a challenge statement to prevent STF type of injuries, as part of the Building and Construction Authority’s (BCA) Built Environment Accelerate to Market Programme (BEAMP) in April 2020.

The team worked with a technology vendor, Vulcan AI, who won the prize money of $30,000 at BEAMP, to co-develop a solution involving wearable watches and CCTV video analytics that can capture near-miss incidents.

|

|

Vulcan AI’s wearable watches can capture near-miss incidents and identify hazards. Vulcan AI’s wearable watches can capture near-miss incidents and identify hazards.

|

|

“What these technologies do is capture these incidents as they provide useful data points,” explained Mr Yeo. Once a hazard is identified, be it poor housekeeping or a slippery oil patch, the supervisor on-site can then rectify the issue promptly. It could also identify workers who are prone to STF, to facilitate further investigation of the root cause which could be fatigue or simply worn-out footwear.

Vulcan AI’s wearable watches have been commercialised and are supported under IMDA’s Advanced Digital Solutions scheme. Currently, the solution is undergoing further development via the BEAMP Market Development phase to expand the features to include health monitoring and productivity measurements to ensure workers are allocating the appropriate amount of time for different work activities.

GETTING MORE COMPANIES ON BOARD

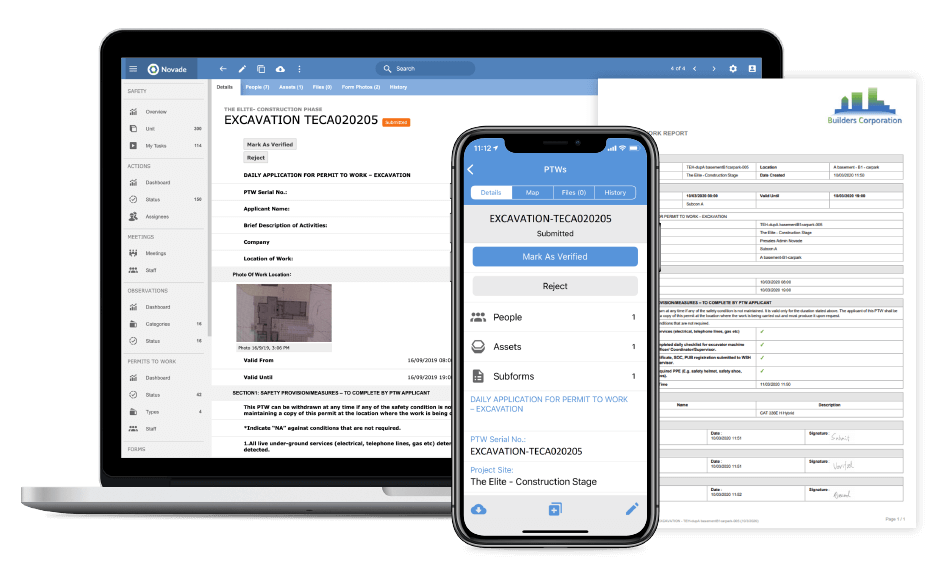

Another tool that is gaining traction is the Electronic Permit-to-Work (ePTW) system, which digitalises the PTW processes. While pen and paper were used before, PTW for high-risk activities can now be managed and monitored through a digital authorisation system, reducing paperwork and saving time.

|

|

The Electronic Permit to Work (EPTW) system automates the processing of permits to work on selected high-risk activities. The Electronic Permit to Work (EPTW) system automates the processing of permits to work on selected high-risk activities.

|

|

For example, an ePTW system ensures proper checks are completed before starting work-at-height activities and a qualified person has approved the PTW.

“It can prevent falsification of permits as there are audit trails and geotagging to ensure the right person is carrying out the right tasks at the right place,” said Mr Yeo. “Supervisors can also have an overview of all the permits that are at the construction sites, all on one platform.”

Moving into new digital terrains, however, can be daunting for some companies. “In such cases, they can start small in selected areas and if it works, they can expand to other areas,” Mr Yeo advised.

Ultimately, companies should view these technology investments as beneficial to both the workforce and the workplace. “When workers know that they are working safely, they have peace of mind and become more productive. Without having to decide between getting the job done or taking risks, workers also feel less stressed and are better able to make good judgements. It’s like a feedback loop.” he said.

To adopt these technology solutions, local SMEs can apply for:

- The Productivity Solutions Grant (PSG), which co-funds up to 70% of the qualifying costs of adopting pre-approved digital solutions under the Construction and Facilities Management Industry Digital Plan, up to a cap of $30,000 per firm.

- The Advanced Digital Solutions (ADS), which funds up to 70% of the qualifying cost of the digital solutions.