Project Team

Owner: Global Switch (Property) Singapore Pte Ltd

Architect: AWP Pte Ltd

Structural Engineer: Meinhardt (Singapore) Pte Ltd

M&E Engineer: Aurecon (Pte) Ltd

Main Contractor and MEP Module Supplier: Gammon Pte. Limited

The first project in Singapore to adopt prefabricated Mechanical, Electrical and Plumbing (MEP) system on a large scale, the Global Switch Singapore Woodlands Data Centre deployed approximately 350 MEP modules. As all the modules were prefabricated offsite, the project was able to achieve higher quality control, savings on manpower and construction time, as well as improved standards of safety.

Global Switch is one of the world’s leading data centre providers. While planning to develop its second data centre in Singapore, the company had one key requirement – to have their high-quality building completed within a short construction period.

Traditionally, MEP works are carried out after structural works, often resulting in extremely tight deadlines for the MEP tradesmen . In this case, the adoption of prefabricated MEP methods helped the project team to get around this issue and reduce the construction period by more than 10%.

MEP modules adopted

- Horizontal modules

- Raised floor modules

- Riser modules

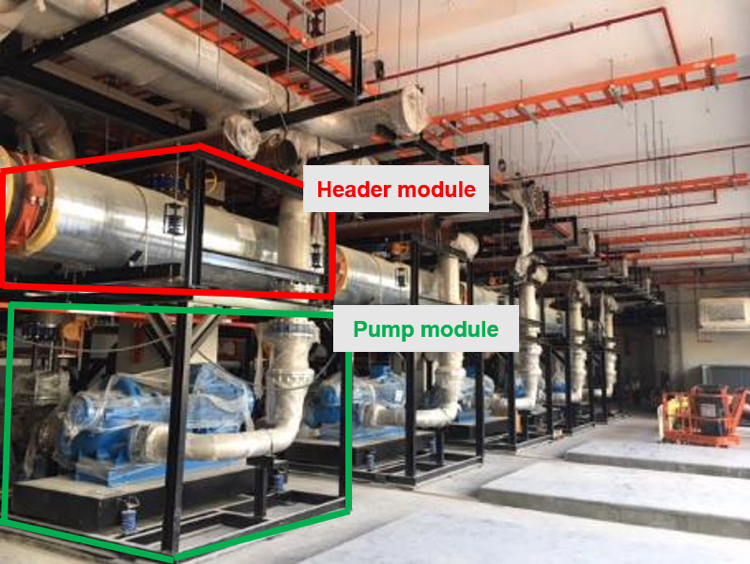

- Pump skid and Header

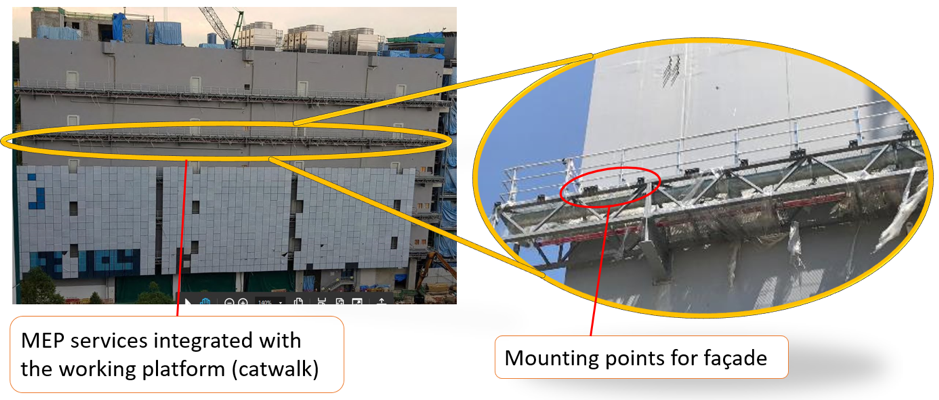

- External façade and catwalk modules

- Roof air-conditioning pipe modules

1. Horizontal modules

2. Raised floor modules

3. Riser modules

4. Pump skid and Header

5. External façade and catwalk modules

6. Roof air-conditioning pipe modules

Module production and installation process example – Riser modules